- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Brochure

- Brochure

- Automotive

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Oil and Gas

- Solutions

- Automation

- Automation

- Control Panels in Hazardous Locations

- Control Panels in Hazardous Locations

- Machine Safety in Hazardous Locations

- Machine Safety in Hazardous Locations

- Solutions

- Oil and Gas

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Special Vehicles

- Solutions

- Construction Site Safety

- Construction Site Safety

- Illuminated Switches

- Illuminated Switches

- LED Pilot Light

- LED Pilot Light

- Auto Machinery

- Auto Machinery

- Rugged Switch

- Rugged Switch

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Robotics

- Solutions

- Robot Safety Switches

- Robot Safety Switches

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Warning System

- Robot Warning System

- Solutions

- Brochure

- Brochure

- Robotics

Smart Palletizing Robot Safety | Canada

Prevents packaging errors by reliably detecting falling objects dropped by palletizing robots

Dropped workpieces could not be detected in a timely manner

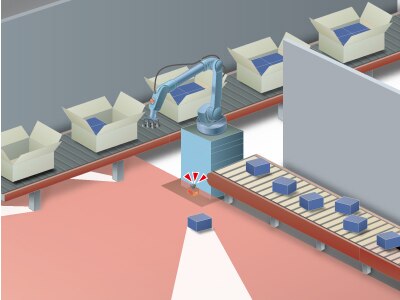

In a large number of food processing and cosmetic production facilities, palletizing robots are used instead of humans to pack products into boxes. Palletizing robots with inbuilt safety measures are responsible for improving production efficiency and eliminating the problem of labor shortages at production sites.

However, these robots are poor at handling small, light, and slippery objects which are often dropped during pickup and transportation. For some objects with particular shapes, there are cases where robot incorrectly drops several pieces out of a 100 pieces. Therefore, box packing area mat sensors can be used to detect dropped objects and reduce the risk of packages having insufficient quantities of products.

When the sensor detects a falling object, the worker usually picks it up and places it in the appropriate cardboard box. However, mat sensors have the inherent weakness of not being able to reliably detect light objects. This means that even if an object drops down, the worker may not be notified due to the mat sensor failing to be triggered. In such a case, insufficient quantities of packaged products are not discovered until the inspection process. This places a heavy burden on the person in charge of inspection.

Using laser scanners helps to detect falling objects, and provides extra safety measures

In order to properly detect falling objects and enable workers to respond immediately, IDEC recommends using the SE2L safety laser scanner instead of mat sensors.

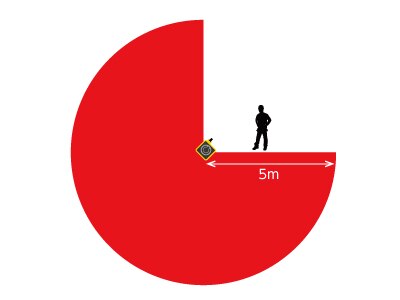

The SE2L safety laser scanner has a detection range of 270 degrees within a distance of 5m. It can reliably detect falling objects regardless of their weight or size.

Furthermore, as a worker approaches a palletizing robot, it is also possible to automatically decelerate or stop the robot according to the distance. This contributes to both safety and productivity while preventing injury or death.

Some customers may be concerned about increased costs associated with the extra functionality. However, because a single unit is capable of covering multiple work areas at once, this means that overall costs are reduced due to eliminating the need to install multiple mat sensors.

Contact IDEC if you have any concerns regarding improving production site productivity and safety

In addition to the SE2L safety laser scanner, we also provide a number of solutions to increase workplace safety.

We have a comprehensive lineup of safety equipment including the LH1D surface mounting indicator lamp that lights up to alert the user of the robot operating state, the FS1A safety controller that allows easy construction of safety circuits via simple logic selection and eliminates the need for programming skills, the HS5L interlock switch with solenoid for safety fence applications, and the RF1V force guided relay for use in safety circuits. Please contact IDEC for more information regarding ensuring worker safety and standardization practices for safety construction.