- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Automotive

- Solutions

- Explosion-Proof Lighting

- Explosion-Proof Lighting

- Robot Collaboration

- Robot Collaboration

- Dual-Action Interlocking

- Dual-Action Interlocking

- Smart Safety Gates

- Smart Safety Gates

- Large Inductors

- Large Inductors

- Small Equipment Safety

- Small Equipment Safety

- Solutions

- Brochure

- Brochure

- Automotive

- Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

-

Food and Packaging

- Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

-

Solutions

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Waterproof Switches

- Waterproof Switches

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Smart Emergency Stop

- Smart Emergency Stop

- Brochure

- Brochure

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Relays

- Smart Relays

- Brochure

- Brochure

- Oil and Gas

- Solutions

- Automation

- Automation

- Control Panels in Hazardous Locations

- Control Panels in Hazardous Locations

- Machine Safety in Hazardous Locations

- Machine Safety in Hazardous Locations

- Solutions

- Oil and Gas

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Compact Equipment

- Compact Equipment

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Brochure

- Brochure

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Maintenance Safety

- Smart Maintenance Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Brochure

- Brochure

- Special Vehicles

- Solutions

- Construction Site Safety

- Construction Site Safety

- Illuminated Switches

- Illuminated Switches

- LED Pilot Light

- LED Pilot Light

- Auto Machinery

- Auto Machinery

- Rugged Switch

- Rugged Switch

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Robotics

- Solutions

- Robot Safety Switches

- Robot Safety Switches

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Warning System

- Robot Warning System

- Solutions

- Brochure

- Brochure

- Robotics

Smart Controllers | Canada

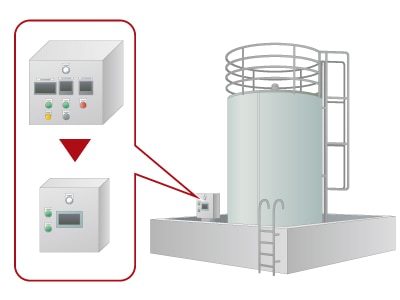

Consolidate several control equipment into a controller with display

Challenges in achieving both high performance and total cost reduction

An engineer of food processing equipment at a manufacturer which provided total services from food processing machines to packaging machines and plant engineering was working on PET bottle drink filling machine development. Considering safety, a large size operation box was used for drink filling machines to prevent accidents from occurring. It was intended to ensure safety of operators by forcing them to use both hands so that neither hand is free. However, users who introduced a filling machine mentioned that it was heavy and difficult to handle during manual operation of the filling machine or maintenance.

IDEC proposed a method which contributed to total cost reduction in designing a control panel. So what was the method?

Consolidate several control equipment into a controller with display

IDEC proposed a solution to achieve both high performance and total cost reduction by using the compact FT1A Touch, a controller that had both a display and control function. Storage tanks for food need to keep temperature constant in order to control quality of food, so control equipment such as temperature control devices including heating and cooling devices, and PLCs for control are used. Furthermore, display devices to indicate temperature and values for monitoring the control status are also used. Previously, several control equipment such as display devices, temperature devices, and PLCs were needed, but with FT1A Touch, functions are consolidated into one. By doing so, control panels are can be made smaller and the number of parts can be reduced to create less work in wiring and designing, which contribute to total cost reduction.

Also, digital and analog control, data logging of temperature inputs using thermocouples is possible. The status of fluid control using tank levels and electromagnetic valves can be recorded as data, making it easy to analyze the data using PC.

The engineer is very satisfied with using the product as control panels are significantly smaller than before and wiring and maintenance time is reduced. He is considering the use of the FT1A Touch on other food processing machines.

Line up of various control devices provides solutions for the production floor

IDEC provides high-quality control and safety devices such as PLC, HMI, pushbutton switches, pilot lights relays, safety switches, emergency stop switches, enabling switches, safety laser scanners, and safety controllers and has a positive reputation for having the most safety assessors in the industry. IDEC can provide your company with consulting on overall safety solutions for your manufacturing floor, not just on safety devices.

Please contact IDEC if you have any concerns about safety measures.