Social Rule Formation / International Standardization |

Solving social issues through the formation of social rules

IDEC has been involved in the formation of social rules through active participation in international standardization activities.

From the 1960s to the 1990s, IDEC expanded its market mainly by utilizing existing rules, but since the 1990s, IDEC has actively participated in technical committees of IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization), proposing and promoting international safety standards in response to new technological developments in the global society.

IDEC itself has been active in shaping the rules by proposing and promoting the development of international safety standards in response to new technological developments in the global community. And since 2017, by focusing on activities to create rules based on new ideas such as Vision Zero and well-being, we aim to achieve our Purpose: “to create the optimal environment for human and machines, and to achieve safety, ANSHIN, and well-being for people around the world."

International standardization activities are defined in the following three categories, and we have established a dedicated unit, the International Standardization and Collaborative Safety Department, within our headquarters to promote a variety of activities.

Among the three categories, we are particularly focusing on “creative” and “proactive” international standardization activities, which we advocate to the world with Japanese leadership. We are also aiming for further growth of our business through continuous human resource development through on-the-job training.

Types of international standardization activities at IDEC

International Standardization Activities

IEC standardization activities

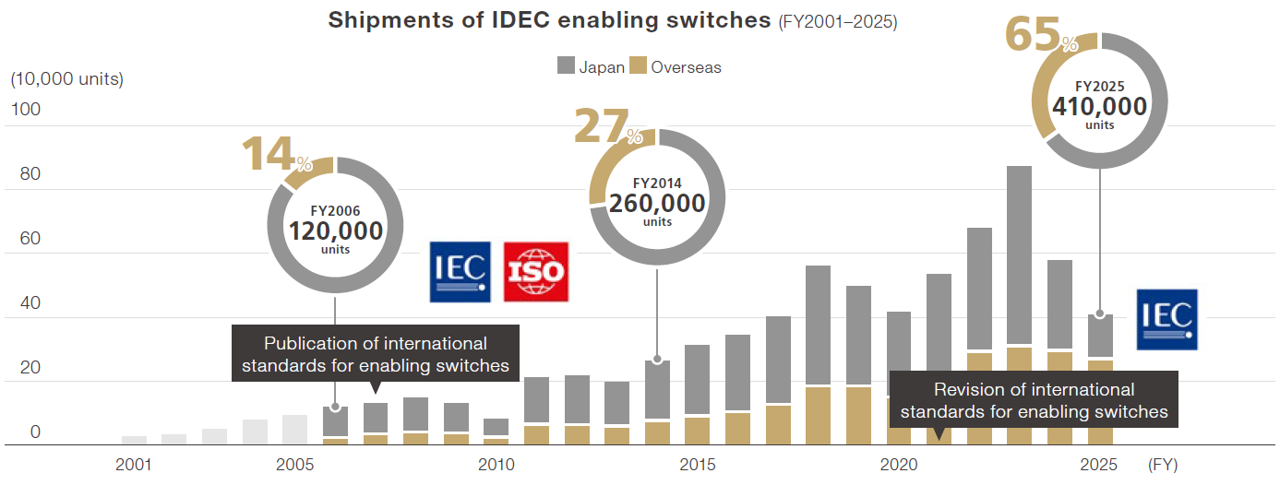

Of the seven technical advisory committees established in the IEC, IDEC represented Japan in the IEC Advisory Committee on Safety (IEC ACOS), where we introduced collaborative safety (safety 2.0) and proposed the need to create an IEC guide on collaborative safety. As a result, the development of the IEC Guide was approved in 2022, and it is expected to be officially published after a vote in each country. By participating in the development of international standards, IDEC has made significant contributions to the development of standards for three-position enabling switches, which have a global market share of over 90%, as well as the revision of standards for emergency-stop switches.

ISO standardization activities

On robot safety, IDEC participates in the Working Group (WG) of the Technical Committee and contributes to the development of the ISO 10218 series, an international standard for the safety of various industrial robots, including collaborative robots and their systems. Additionally, IDEC is involved in the Working Group of the Technical Committee of the safety of automated guided vehicles (AGV, AMR, AGF, etc.), which have been increasing in number in recent years, and contributes to the development of ISO3691-4, an international safety standard.