FT1J 4.3inch PLC+HMI

All-in-One PLC and HMI:

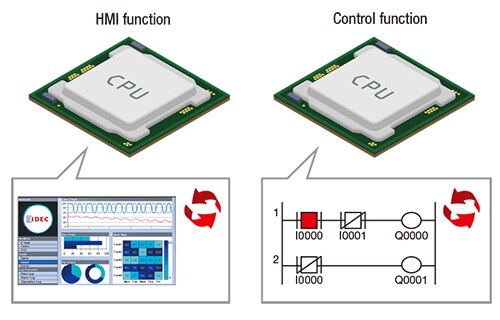

This compact yet powerful 4.3-inch all-in-one unit combines a Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) to deliver superior performance and functionality. With its dual CPU structure, it optimizes scan time for faster, more efficient processing.

Advanced PLC Control Capabilities:

The unit comes equipped with onboard I/O and offers expandable I/O options to meet various application needs. Built-in analog inputs and outputs provide seamless integration for complex control tasks. Designed to support advanced control features, the unit includes PID control, Pulse Width Modulation (PWM), high-speed inputs, and script programming, giving you the flexibility to tackle a wide range of automation challenges.

Intuitive Touchscreen Interface:

The HMI side uses advanced Projected Capacitive (PCAP) technology, offering high visibility, durability, and functionality. It supports multi-touch gestures and is designed to prevent accidental inputs from water droplets, ensuring reliable operation in various environments.

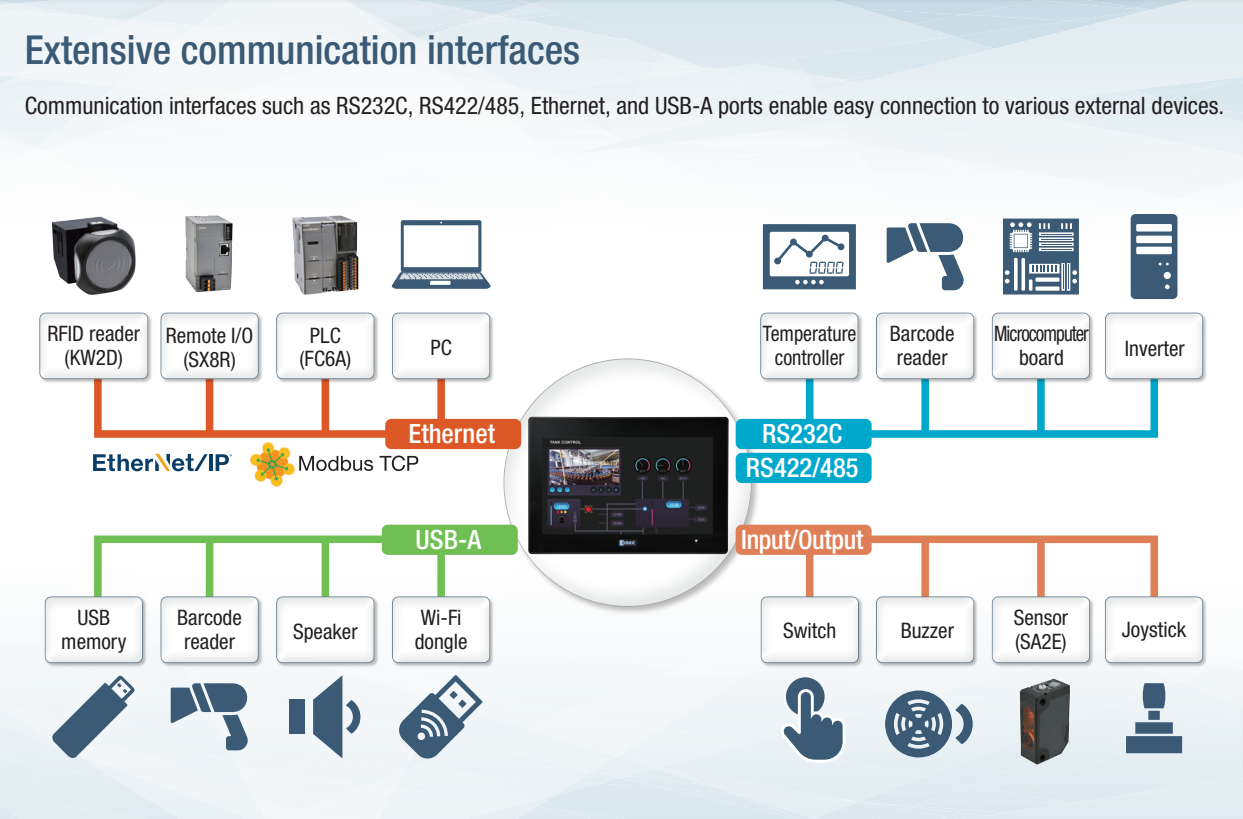

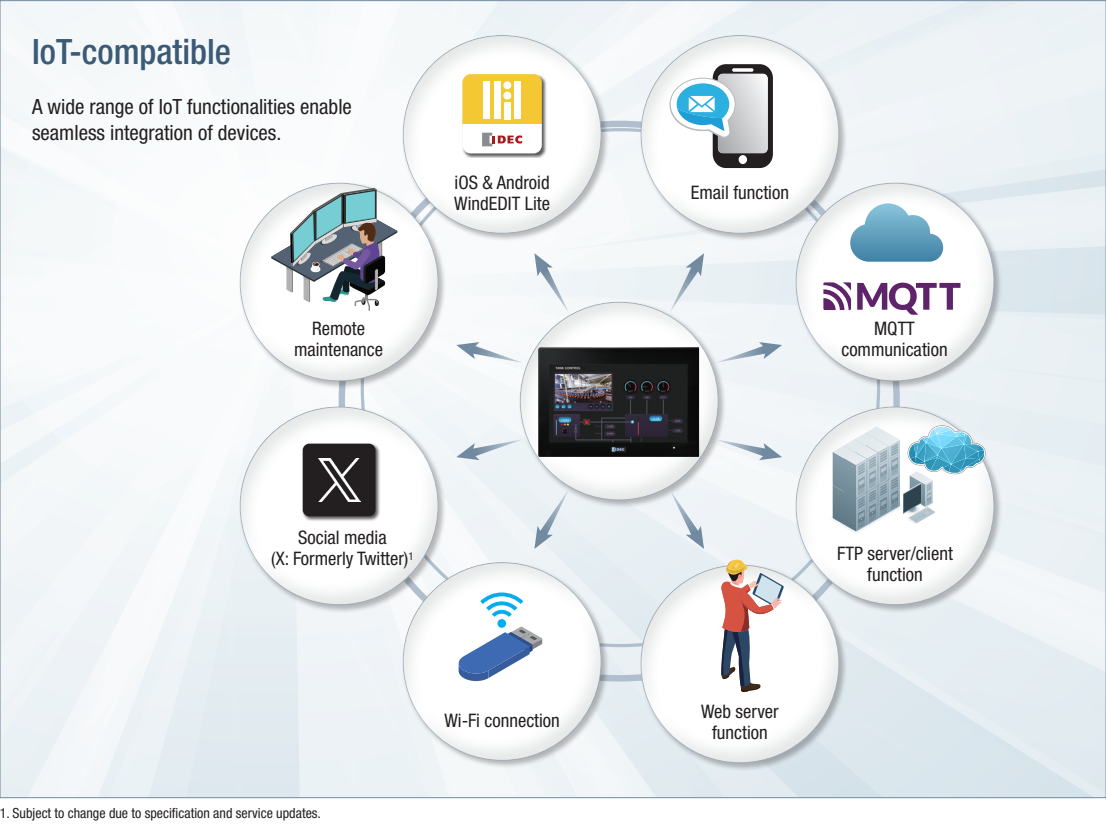

In addition to its robust hardware, the unit supports open communication protocols like EtherNet/IP, Modbus TCP/IP, and BACnet/IP, as well as IIoT features such as MQTT, making it ideal for modern industrial applications.

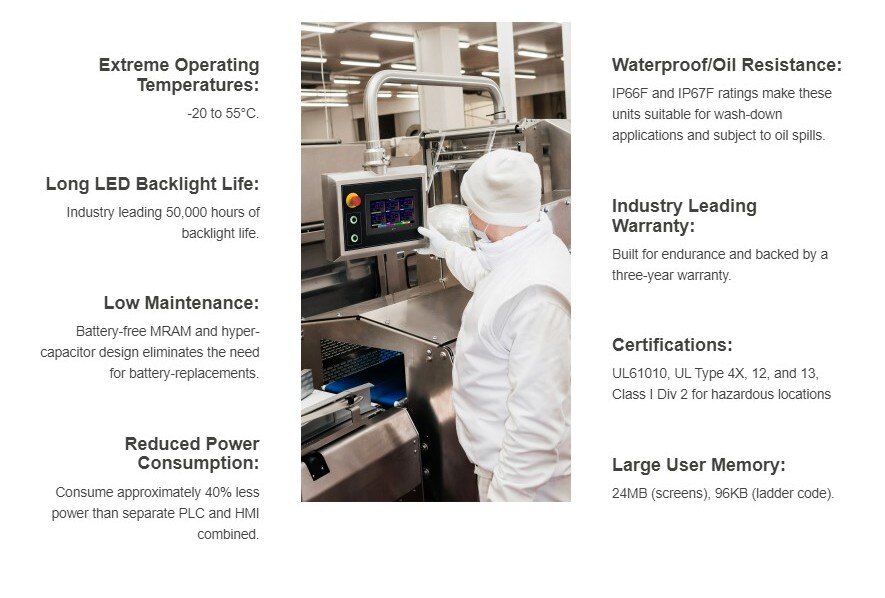

Key Features:

Product Video

Adaptable Hardware

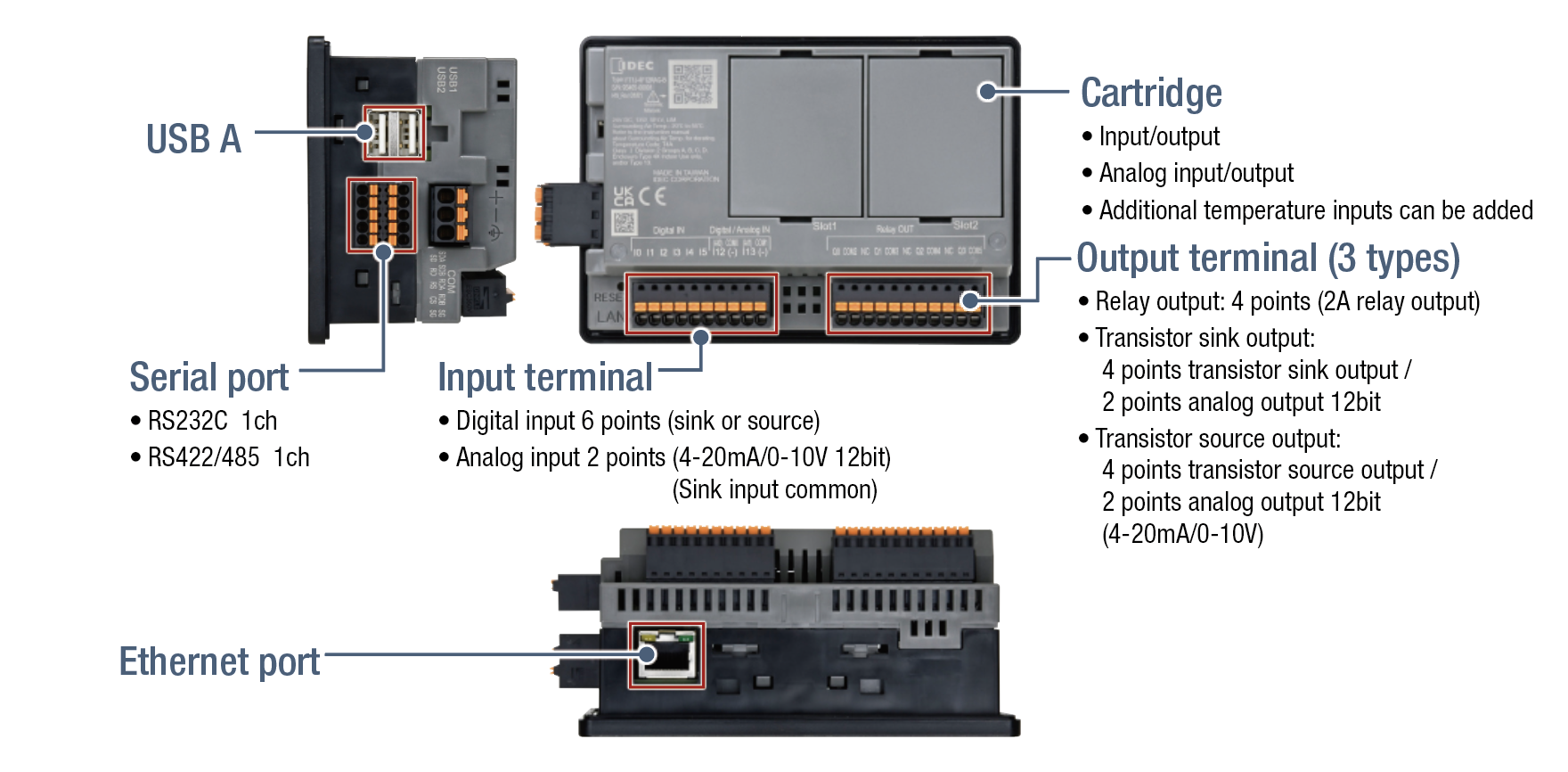

FT1J Input/output points: up to 22 (analog/digital)

Dual CPU configuration for high-speed processing

The FT1J and FT2J feature two CPUs working in parallel for the PLC and HMI. This design enables high-speed, real-time control without compromising HMI functionality, broadening the range of compatible applications.

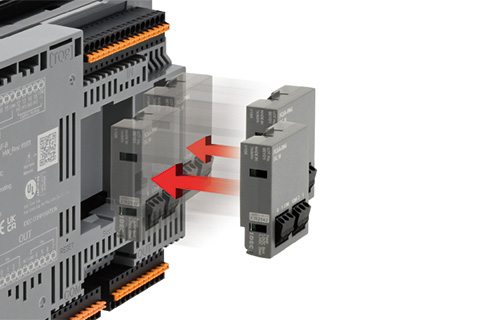

I/O Expansion with Cartridges

Up to 2 digital I/O cartridges or analog I/O cartridges can be connected, to add up to 8 digital I/O and up to 4 analog I/O.

Analog I/O

Equipped with a built-in analog I/O to control analog signals from 0 to 10V DC (4 to 20 mA) with 12-bit resolution. An analog potentiometer connected to the analog input allows for easy configuration of analog settings, such as a timer.

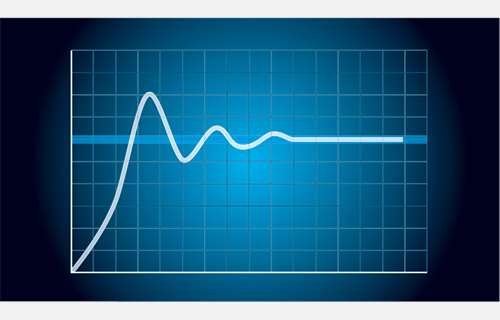

PID Temperature Control

A PID algorithm is used to enable cascade control. Available for applications requiring temperature, flow, and pressure control.

Open Network

Highly Visible Glass-Top Structure

Easily kept clean using chemical washdown or simple wipes. Besides being water- and scratch-resistent, PCAP is responsive and provides high tolerance to resist false signals when dirt or water droplets are present on the face of the HMI.

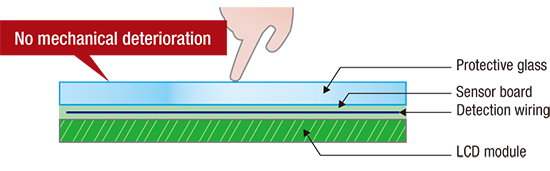

No Mechanical Durability Issues

The PCAP touch panel uses a sensor board to detect changes in electric charge to identify the position of the touch. There is no mechanical deterioration, allowing for agile operation, and multi-touch sensing gloves less than 1.5mm thick1 can be used.

1. The touchscreen may not work with gloves thicker than 1.5mm, depending on the material of the gloves and environment.

High Durability and Advanced Features

Seamless Communication with Various Devices